Product Description

Producs description:

1.Material: PU

2. Hardness: Durometer 70-90 Shore A

3.Color: red,black,yellow

4.Logo & Printing: according to your request.

5.Application: Auto Electronic products, Machine etc

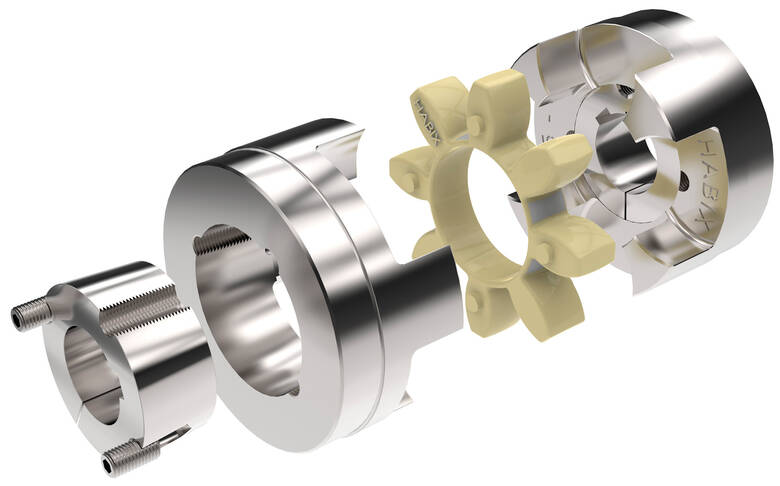

Plum CHINAMFG mat, full name plum-shaped elastic coupling cushion. It is used for cushioning of various heavy machinery coupling shafts. Some areas are also known as plum CHINAMFG plates. According to the material, it can be divided into polyurethane plum mat and rubber plum mat, nylon plum mat.

Plum CHINAMFG mat is divided into MT type plum CHINAMFG mat, T-shaped hexagonal mat, GR star plum CHINAMFG mat, HRC hexagonal mat, NM type elastic ring, L-shaped hexagonal pad, NL nylon inner tooth sleeve, H-type elastic block, rubber gear, etc.

The plum CHINAMFG pad is used for damping, insulation and buffer transmission torque in the middle of the coupling. The torque transmitted by the plum CHINAMFG pads of different materials and different hardness is also different. The higher the hardness, the greater the torque transmitted

packing and shipping

packing: carton box and pallet.

shipping: according to your quantity, usually 5-30 days after your payment.

Company Brief Introduction:

SHEN ZHOU AOKAI RUBBER & PLASTIC CO.,LTD was founded in 2000. The factory located in industrial zone of HangZhou city, ZheJiang province, china.

We have Plastic injection molding workshop and rubber compression molding workshops.

Our main products includes Bakelit Knobs,Pull Handle,rubber door stops, door guard, roller, rubber bumpers, Rubber grommets, vibration dampers, seals, plastic corner, injection plastic brackets, injection plastic shell.

to undertake various kinds of rubber molding and plastic injection parts, customize according to drawing and samples.

The products have been exported to America, Europe, Oceania, Middle East, Southeast Asia and other regions and countries, and hope to build more business Cooperation with new client from all over the world.

Why choose us?

1.Our company was founded in 2000, have rich experience in production.

2.Product from purchased materials, processing, assembly, have strict quality control.

3.We have our own production plant, products more cheaper.

4.The company has specialized production lines and perfect testing facilities.

5. Our service formula: Good quality,cheap price and good service.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Compensation for Misalignment in Elastic Couplings

Elastic couplings are designed to accommodate certain degrees of misalignment between connected components in mechanical systems. The elastomeric material used in the coupling plays a crucial role in this compensation process:

When the two components connected by the elastic coupling experience angular, parallel, or axial misalignment, the elastomeric material deforms to a certain extent. This deformation allows the coupling to maintain its connection while absorbing the misalignment-induced stresses and forces.

The elastomer acts as a flexible link between the components, allowing them to move relative to each other within specified limits. The deformation of the elastomer also helps distribute the load more evenly, reducing stress concentrations and the risk of premature wear or damage to the coupling or connected components.

Elastic couplings can compensate for both static and dynamic misalignment, making them suitable for applications where minor misalignment is unavoidable due to factors such as manufacturing tolerances, thermal expansion, or vibration.

It’s important to note that while elastic couplings can accommodate misalignment, excessive misalignment should still be avoided, as it can lead to accelerated wear and reduced coupling lifespan. Regular inspection and maintenance are recommended to ensure that the coupling is operating within its designed limits.

Contribution of Elastic Couplings to Rotating System Efficiency

Elastic couplings play a significant role in enhancing the overall efficiency of rotating systems by providing various benefits:

1. Vibration Damping: Elastic couplings absorb and dampen vibrations and shocks that arise from the operation of rotating machinery. By minimizing these vibrations, elastic couplings reduce wear and tear on components, leading to smoother operation and extended component lifespan.

2. Misalignment Compensation: Rotating systems often experience misalignments due to factors like thermal expansion, installation errors, or operational conditions. Elastic couplings can accommodate angular, axial, and radial misalignments, ensuring consistent power transmission and reducing stress on connected components.

3. Shock Absorption: In applications with sudden starts, stops, or load changes, elastic couplings absorb and distribute shock loads. This prevents sudden jolts that could damage the machinery or cause mechanical failures.

4. Torsional Vibration Reduction: Elastic couplings help minimize torsional vibrations, which can lead to resonance and cause structural damage. By damping these vibrations, elastic couplings prevent energy loss and ensure smooth operation.

5. Energy Efficiency: The ability of elastic couplings to reduce vibrations, misalignments, and shock loads leads to improved energy efficiency. The machinery experiences fewer energy losses due to internal friction and component stress.

Elastic couplings enhance the reliability, longevity, and performance of rotating systems, ultimately leading to reduced downtime, maintenance costs, and overall operational inefficiencies.

Factors to Consider When Selecting an Elastic Coupling

Engineers must carefully evaluate several factors when selecting an appropriate elastic coupling for a specific application. These factors ensure that the coupling can effectively meet the requirements of the machinery and system:

- Torque Transmission: Consider the amount of torque that needs to be transmitted between the connected shafts. Ensure that the coupling’s torque rating matches or exceeds the application’s torque requirements.

- Misalignment Compensation: Evaluate the expected misalignments between the shafts, such as angular, parallel, and axial misalignments. Choose a coupling with the appropriate flexibility and misalignment capacity to accommodate these variations.

- Vibration Dampening: Determine the level of vibration present in the system and select a coupling with the necessary torsional elasticity to dampen vibrations and provide smoother operation.

- Operating Speed: Consider the rotational speed of the connected shafts. Some elastic couplings may have speed limitations, so choose a coupling that can handle the desired operating speed without issues.

- Environmental Conditions: Assess the operating environment, including temperature, humidity, and the presence of contaminants. Choose a coupling material that can withstand the conditions and resist corrosion or degradation.

- Space Limitations: Take into account the available space for installing the coupling. Some couplings may have compact designs that are better suited for confined spaces.

- Shaft Sizes: Ensure that the coupling is compatible with the diameters of the connected shafts. Verify the coupling’s bore sizes and choose one that matches the shaft sizes.

- Installation and Maintenance: Consider the ease of installation and maintenance. Some couplings have simpler installation procedures, while others might require more complex procedures.

- Cost: Evaluate the budget for the coupling. While high-performance couplings might have added benefits, they could also come at a higher cost. Balance the performance requirements with budget constraints.

By carefully assessing these factors and selecting the appropriate elastic coupling, engineers can ensure optimal performance, longevity, and reliability of the machinery and systems they design.

editor by CX 2024-02-24