Product Description

HGTQ Series Application:

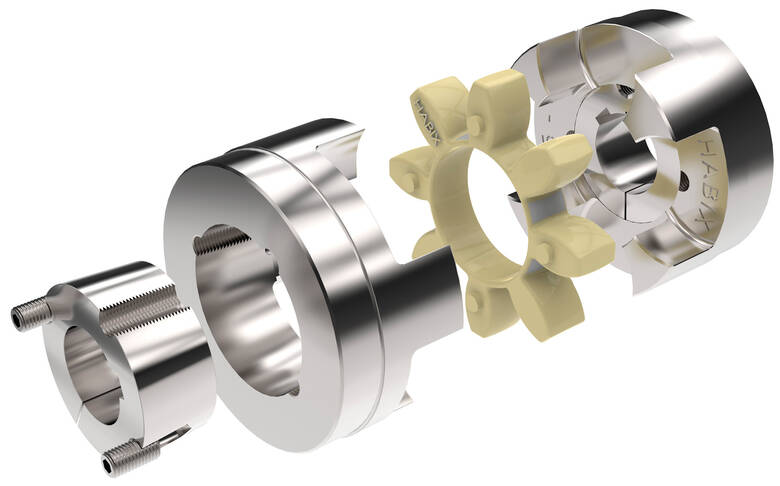

HGTQ series high-elastic coupling is a kind of torsion type high-elastic coupling. It is suitable for other medium and high-powered gearboxes produced by our company, and is also suitable for other power transmissions mainly powered by diesel engines and motors. . The structure mainly comprises a vibration damping ring assembly, an elastic plate and a main and driven end connecting member, which can effectively compensate radial, angular and axial displacement of adjacent machinery, absorb vibration, reduce resonance speed, and thereby improve shafting torsion. Features to extend equipment maintenance intervals and service life.

This series of high-elastic couplings has a rated torque range of TKN30=5-31.5kNm for a total of 9 size groups. Nearly 1 hundred HCT1100, HC1200, HC1250 and HCQ1400 have been matched before the official production. After nearly 5 years of trials, this series of high-elastic couplings is a new cost-effective product.

Products Introduction:

The Company’s high elastic couplings digesting and absorbing German advanced technology were the result of self-R&D together with HangZhou Research Institute of Marine Gearbox, being recognized by CCS, ZY, BV, ABS, RINA, NK and LR. The company has passed through ISO9001:2008 accreditation.

The Company has made itself available with perfect means of inspections. It has R&Ded dynamic tester on high elastic coupling – a fully independent intellectual right of our own – the first 1 of this type in China.

Realizing zero rate of service due to product quality for 6 years in a row and achieving average use life of 7 to 8 years for easy worn-out parts, the Company has been the top 1 in this line in China in terms of capacity and market share.

The concept of service: being devoted to ensuring customer satisfactions. The concept of management of maintaining standard institutions and advanced manufacturing and inspection equipment, being brave for innovations and making continuous improvements is essential to ensure quality products. A cordial welcome will be given for visit and guidance.

HGTQ structure introduction:

1. The elastic element is ring-shaped, and the vent hole is arranged in the middle of the ring, which is beneficial to ventilation and heat dissipation. The diaphragm part can attenuate the axial reaction force, and protect the main and auxiliary machines. The 2 connection modes commonly used at the output end are applicable. In different installation spaces and working conditions, special connection methods can also be designed according to user requirements. The single-row elastomer has low relative cost, but the dynamic stiffness is relatively large, which is suitable for medium and high-speed diesel engines.

High-elastic products approved by the world’s multinational classification societies

.

HGTQ Series products Suitable for independent rigid or elastic power transmission devices installed by the host,

Rated torque range 0.8-31.5kN.m

90% of the flexible installation of the “ADVANCE” light gearbox

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Reducing Vibration and Shock in Machinery with Elastic Couplings

Elastic couplings play a crucial role in minimizing vibration and shock in machinery by offering flexibility and damping characteristics. Here’s how they contribute to this important function:

- Vibration Absorption: Elastic couplings are designed with flexible elements that can absorb and dampen vibrations generated by rotating machinery. These flexible elements act as shock absorbers, reducing the transmission of vibrations to other parts of the system.

- Isolation: The inherent flexibility of elastic couplings isolates vibrations and shocks from one side of the coupling to the other. This prevents vibrations from propagating throughout the connected components, helping to protect sensitive equipment and improve overall system performance.

- Resonance Damping: Elastic couplings can help dampen resonance frequencies that can occur in machinery during operation. By absorbing and dissipating energy, they reduce the risk of resonance-related issues that can lead to mechanical failure or decreased efficiency.

- Smooth Torque Transmission: Elastic couplings offer a smooth torque transmission that helps reduce sudden torque spikes and shocks during start-up or sudden load changes. This prevents abrupt mechanical stresses that can lead to vibration and shock propagation.

- Increased Equipment Lifespan: By minimizing the impact of vibrations and shocks, elastic couplings contribute to the longevity of connected machinery and components. Reduced vibration-related wear and tear can extend the service life of the entire system.

Overall, elastic couplings are effective tools for managing vibration and shock in machinery, enhancing operational reliability, reducing maintenance needs, and maintaining optimal performance.

Alternatives to Elastic Couplings for Flexible Connections in Machinery

There are several alternatives to elastic couplings for achieving flexible connections in machinery:

1. Universal Joints: Universal joints, also known as U-joints, are mechanical devices that allow rotational motion between two shafts at different angles. They are suitable for applications with significant misalignment.

2. Cardan Shafts: Cardan shafts consist of a series of universal joints connected in a line, allowing for the transmission of torque and rotation in complex systems.

3. Oldham Couplings: Oldham couplings use sliding disks to transmit torque while accommodating small misalignments. They are suitable for applications where precise positioning is required.

4. Beam Couplings: Beam couplings use a flexible beam to transmit torque and compensate for angular and axial misalignment.

5. Diaphragm Couplings: Diaphragm couplings use thin diaphragms to transmit torque while compensating for misalignment. They are often used in high-performance applications.

6. Gear Couplings: Gear couplings use teethed gears to transmit torque and accommodate misalignment. They are suitable for heavy-duty applications.

7. Chain Couplings: Chain couplings use roller chains to transmit torque and handle misalignment. They are commonly used in low-speed, high-torque applications.

8. Bellows Couplings: Bellows couplings use a bellows-like flexible element to transmit torque while compensating for misalignment.

Each of these alternatives has its own advantages and limitations, and the choice depends on the specific requirements of the application.

Industries Using Elastic Couplings

Elastic couplings find extensive use in various industries due to their unique benefits:

- Industrial Manufacturing: Elastic couplings are widely used in manufacturing equipment, conveyors, and assembly lines to maintain smooth operation and reduce vibrations.

- Automotive: Automotive applications include engine components, powertrain systems, and vehicle suspension systems where flexibility and vibration dampening are crucial.

- Power Generation: Elastic couplings are used in power generation equipment such as generators, turbines, and pumps to absorb torsional vibrations and enhance efficiency.

- Aerospace: In aerospace applications, elastic couplings help dampen vibrations in critical components like aircraft engines and control systems.

- Renewable Energy: Wind turbines and solar tracking systems benefit from elastic couplings to accommodate misalignments and vibrations caused by changing wind conditions.

- Mining: Mining equipment such as crushers, conveyors, and screens utilize elastic couplings to handle varying loads and minimize shock loads.

- Marine: Elastic couplings are used in marine propulsion systems and ship equipment to manage torque fluctuations and reduce vibrations.

These industries rely on elastic couplings to enhance performance, extend machinery lifespan, and minimize downtime due to vibrations, misalignments, and shock loads.

editor by CX 2024-04-19